Molecular Modeling and Design of Hybrids

We address fundamental questions related to the mechanical and fracture properties of molecular hybrid materials that have application for emerging aerospace and microelectronic technologies. Low-density hybrid materials, which contain organic and inorganic molecular components, can be engineered over a wide range of length scales to exhibit unique combinations of mechanical, thermal, and optical properties desirable for use in mechanically-robust, multifunctional aerospace applications. Hybrid materials are therefore ideally suited to a bottom-up materials design where molecular structure and resulting properties can be engineered and tailored to achieve desired property sets.

Molecular Confinement in Hybrids

We investigate and exploit the effects of polymer confinement inside the pores of hybrid or inorganic matrices, which provides new opportunities to tailor properties. Our research focuses on the smallest molecular length scales of this confinement, where new mechanisms of strengthening and toughening exist that are not found in traditional composite materials. By focusing on the behavior of under extreme confinement, we are able to probe the fundamental limits of strengthening and toughening in nanocomposite materials and find new avenues for innovation

At such high degrees of polymer confinement, toughening of the nanocomposite is found to be dominated by the matrix-polymer interaction. We tune these interactions via chemical modification of the matrix surface, leading to significant changes in the toughness of the resulting nanocomposite. This provides a method of optimizing the mechanical and thermal properties of the nanocomposite.

Fig. 1:Polymer chains infiltrating into nanoscale pores.

While extreme molecular confinement improves the mechanical resilience of composite materials, it can also be expected that the confined molecules themselves will exhibit properties that deviate from their bulk behavior. We are interested in studying these deviations in behavior and utilizing them in applications for which the bulk materials are unfit. Specifically, our research is aimed at understanding the influence of imposed confinement on molecular ordering, crystallization, and optoelectronic behavior of polymers as well as other candidate materials. We are also expanding our library of porous matrices to extend the design space of possible composite films and applications.

To probe the confined material directly we have applied gas cluster ion beam (GCIB) etching to prepare the composites materials for nanomechanical and nanochemical analysis with atomic force microscopy. We demonstrate that the GCIB can effectively remove material and produce damage free surfaces for composites comprised of PMMA or PS confined in the 7 nm diameter pores of an organosilicate matrix to be directly probed with advanced AFM techniques.

Molecular Modeling of Nanomaterials

We use Molecular Dynamics simulations to model nanomaterials to explore fundamental structure-property relationships and design materials with desired properties by tuning the molecular architecture. With Molecular Dynamics simulations, we can generate accurate models of a range of device materials including polymer structures, hybrid glasses and nanocomposites.

An example of detailed modeling of complex molecular structures through Molecular Dynamics simulations:

Design of Mechanically Reliable Hybrids

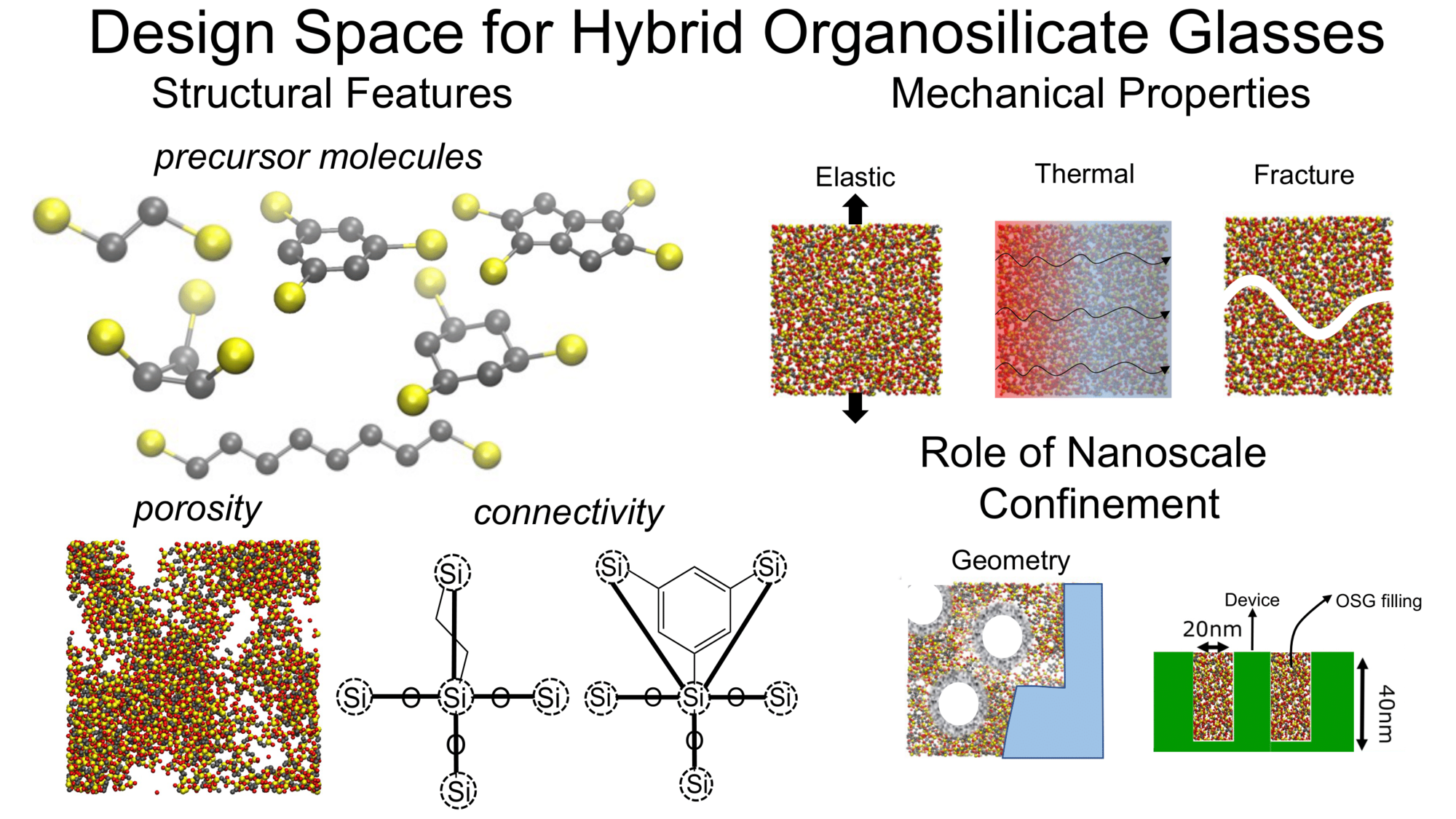

Hybrid organic-inorganic glasses exhibit unique electro-optical properties along with excellent thermal stability. However, their inherently fragile nature remains a fundamental challenge for their integration into nanoscience and energy technologies. A fundamental understanding of the structure-property relationships is, therefore, crucial for the thermomechanically reliable design of these materials.

Karsu Ipek Kilic is working to develop computational methods to address the fundamental relationships between molecular structure and resulting mechanical properties of hybrid organosilicate glasses (illustrated on the left). Using a new simulated annealing approach as part of molecular dynamics simulations in LAMMPS, large distortion-free hybrid glass models with well-controlled network connectivity can be generated from a wide range of organosilane precursors. Both dense and nanoporous hybrids can be modeled.

With these model structures, we can simulate the elastic, fracture, and thermal properties of these materials to establish complex structure-property relationships and design new glasses that exhibit outstanding mechanical properties. One example is the design of ultrastiff hybrid organosilicate glasses that are less dense but stiffer than fully dense silica:

Functional and Transparent Coatings

Atmospheric Plasma Deposition (APD) is an open air, atmospheric pressure chemical vapor deposition technique. We use an atmospheric pressure plasma discharge to fragment and subsequently polymerize small molecules into highly transparent and functional thin films. We constantly develop new processes for the growth of a wide range of materials, including silica, metal oxides, nitrides, and polymer coatings, onto both organic and inorganic substrates. Many emerging device and energy technologies require moisture barriers to prevent water ingress for improved lifetimes. Wearable devices, organic light-emitting diodes, perovskite solar cells, are all examples of technologies which are susceptible to damage in the presence of water. We are using atmospheric plasma deposition to coat moisture-sensitive perovskite solar cells with a multilayer barrier design. Each layer provides unique properties which contribute to overall barrier function and mechanical integrity of the barrier.

A combination of plasma diagnostics and thin film characterization allows us to understand the reaction pathways, providing a feedback loop which helps us optimize our chemistries. Our research effort currently takes advantage of two distinct types of plasma discharge, each offering unique advantages:

- Capacitively Coupled Plasma (CCP)

- Dielectric Barrier Discharge (DBD)

Ziyi Pan leads the efforts on developing encapsulation strategies to protect both perovskite and bifacial silicon solar modules from degrading in environmental conditions of UV sunlight, rain/moisture, and thermal cycling of the night and day. We employ two major strategies: a thin film barrier strategy which is compatible with flexible and thermally sensitive substrates and a bulk encapsulation strategy which is more mechanically robust and allows for enhanced protection. Our thin film barriers are deposited using a scalable open-air plasma deposition process similar to the technique used for perovskite deposition. The bulk encapsulation is composed of a clear adhesive used to adhere either a plastic backsheet or a sheet of glass to protect the module from UV light as well as contaminant/moisture ingress. The eventual goal is to ensure that the efficiency of our modules can be maintained to achieve a 30-year lifetime.

Cross-section SEM image of thin film barrier structure:

Current Research Projects

- Direct Probing of Polymers Under Nanoconfinement

- Functional Nanoporous Metal Oxide Matrices

- Cross-linking of High Performance Polymers Under Confinement

- Computational Analysis of the Structure and Mechanical Reliability of Low-k Hybrid Glasses Under Nanoconfinement

- Elastic Properties of Organosilicate Hybrid Glasses Under Extreme Low Temperatures

- Multilayer Barrier Coatings

Group Members

Past Research Projects

- Advanced Nanocomposite Materials Toughened with Polymers in Extreme Confinement

- Toughening Hybrid Nanocomposites by Chemically Tuning Polymer-Matrix Interaction

- Design of Ultrastiff Hybrid Organosilicate Glasses

- 3-D Fracture Path in Nanoporous Glasses

- Effects of Extreme Confinement on Intermolecular Interactions

- Elastic and Thermal Expansion Asymmetry

- Hyperconnected Hybrid Glass Films with Exceptional Elastic Properties