Nick Rolston

Research Interests

Organic-inorganic metal halide perovskites have received significant attention as a next-generation solar absorber material due to compatibility with solution processing and unprecedented gains in power conversion efficiency on lab-scale devices—comparable in performance to conventional solar technologies—but limitations in device stability and scalability have challenged the path to commercialization. As a result, perovskites in their current form are highly susceptible to degradation and limited in their path to market based on unproven reliability and low-throughput processing methods.

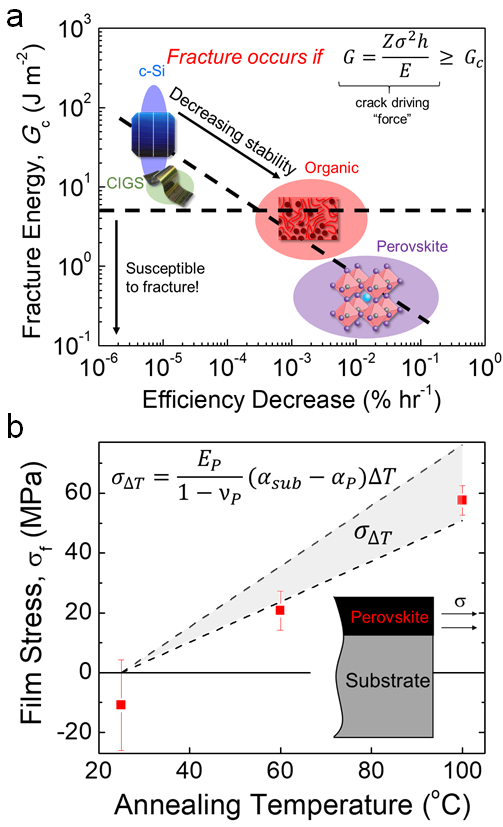

Mechanical properties are excellent predictors for device resilience to environmental stressors that accelerate the evolution of internal defects and cause delamination and device failure in layered structures. The fundamental mechanical and material properties of perovskite solar cells are first investigated to gain insight on relevant degradation modes and failure mechanisms. We have identified perovskites as the most mechanically fragile solar technology (Figure 1a), further complicating the prospect of commercial viability. The mechanical integrity and residual film stresses (Figure 1b) of perovskite materials are connected with device stability, and we have developed strategies to improve the thermomechanical reliability of perovskite solar cells in order to inform design criteria for stable, large-area solar modules.

Figure 1. (a) The measured resistance to fracture (Gc) and degradation rate as a function of solar cell active material, showing a correlation between mechanical integrity and long-term reliability. (b) Measured film stress for perovskite formed at 25, 60, and 100 °C compared to predicted stress from thermal expansion mismatch between the perovskite and substrate (dashed lines).

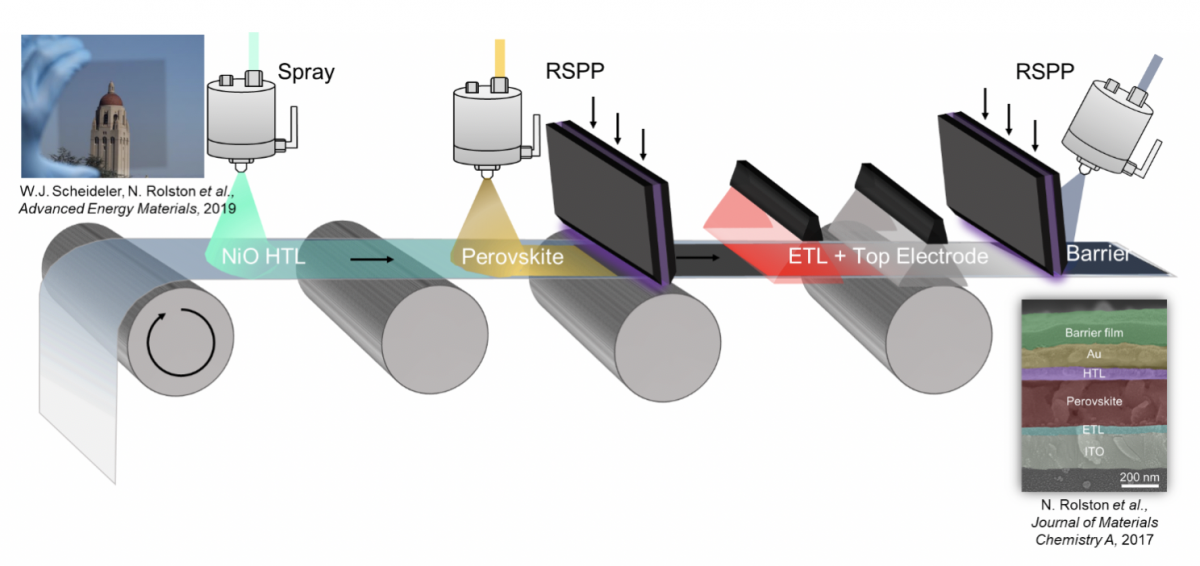

Open-air fabrication methods offer low capital-expenditure routes to perovskite manufacturing, but achieving stable, high performing devices in ambient conditions with varying relative humidity remains a persistent challenge. We demonstrate that Rapid Spray Plasma Processing (RSPP) is a scalable method to deposit robust perovskite films in open-air with linear speeds of 12 m/min without any post-anneal. Alternative processing methods produce devices with a performance that varies based on the relative humidity during processing; however, RSPP is a moisture-resistant process that produces films with improved thermomechanical and optoelectronic properties than traditional solution processing. Manufacturability of RSPP is demonstrated by producing monolithically integrated perovskite solar modules with the highest power per manufacturing hour and lowest cost of any solar technology.

Figure 2. Schematic of a process line adapted for continuous, in-line manufacturing of open-air processed perovskite solar modules.

First Author Publications (*Equal Contribution)

-

A. Giuri*, N. Rolston, S. Colella, A. Listorti, C.E. Corcione, H. Elmaraghi, S. Lauciello, R. Brescia, R.H Dauskardt, & A. Rizzo, “Robust, high-performing maize-perovskite nanocomposite based solar cells with improved stability” in preparation

-

N. Rolston*, W.J. Scheideler*, A. Flick, J.P. Chen, H. Elmaraghi, O. Zhao, M. Woodhouse & R.H. Dauskardt, “Rapid open-air fabrication of manufacturable perovskite solar modules”, Joule, in review

-

N. Rolston*, R. Bennett-Kennett*, L. Schelhas, J.J. Berry, & R.H. Dauskardt, “Comment on “Light-induced lattice expansion leads to high-efficiency perovskite solar cells””, Science, 2020, DOI: 10.1126/science.aay8691

-

M. Gutwald*, N. Rolston*, A.D. Printz, O. Zhao, H. Elmaraghi, Y. Ding, J. Zhang, & R.H. Dauskardt, “Perspectives of intrinsic toughening strategies and passivation of perovskite films with organic additives”, 2020, DOI: 10.1016/j.solmat.2020.110433

-

I. Lee*, N. Rolston*, P.L. Brunner, & R.H. Dauskardt, “Hole transport layer molecular weight and doping effects on perovskite solar cell efficiency and mechanical behavior”, ACS Applied Materials and Interfaces, 2019, DOI: 10.1021/acsami.9b05567

-

N. Rolston*, K.A. Bush*, A.D. Printz, A. Gold‐Parker, Y. Ding, M.F. Toney, M.D. McGehee, & R.H. Dauskardt, “Engineering stress in perovskite solar cells to improve stability”, Advanced Energy Materials, 2018, DOI: 10.1002/aenm.201802139

-

K.A. Bush*, N. Rolston*, A. Gold-Parker, S. Manzoor, J. Hausele, Z.J. Yu, J.A. Raiford, R. Cheacharoen, Z.C. Holman, M.F. Toney, R.H. Dauskardt, & M.D. McGehee, “Controlling thin-film stress and wrinkling during perovskite film formation”, ACS Energy Letters, 2018, DOI: 10.1021/acsenergylett.8b00544

-

N. Rolston, A.D. Printz, J.M. Tracy, H. Weerasinghe, D. Vak, L.J. Haur, A. Priyadarshi, N. Mathews, D.J. Slotcavage, M.D. McGehee, R.E. Kalan, R.L. Grimm, H. Tsai, W. Nie, A.D. Mohite, S. Gholipour, M. Saliba, M. Graetzel, & R.H. Dauskardt, “Effect of cation composition on the mechanical stability of perovskite solar cells”, Advanced Energy Materials, 2018, DOI: 10.1002/aenm.201702116

-

B.L. Watson*, N. Rolston*, A.D. Printz*, & R.H. Dauskardt, “Scaffold-reinforced perovskite compound solar cells”, Energy and Environmental Science, 2017, DOI: 10.1039/C7EE02185B

-

N. Rolston, A.D. Printz, F. Hilt, M.Q. Hovish, K. Bruening, C.J. Tassone, & R.H. Dauskardt, “Improved stability and efficiency of perovskite solar cells with submicron flexible barrier films deposited in air”, Journal of Materials Chemistry A, 2017, 10.1039/C7TA09178H

-

B.L. Watson*, N. Rolston*, L. Taleghani, K.A. Bush, & R.H. Dauskardt, “Synthesis and use of a hyper-connecting cross-linking agent in the hole-transporting layer of perovskite solar cells”, Journal of Materials Chemistry A, 2017, DOI: 10.1039/C7TA05004F

-

N. Rolston, A.D. Printz, S.R. Dupont, E. Voroshazi, & R.H. Dauskardt, “Effect of environmental stressors on decohesion kinetics of organic solar cells”, Solar Energy Materials and Solar Cells, 2017, DOI: 10.1016/j.solmat.2017.06.002

-

N. Rolston, B.L. Watson, C.D. Bailie, M.D. McGehee, J.P. Bastos, R. Gehlhaar, J.E. Kim, D. Vak, A.T. Mallajosyula, G. Gupta, A.D. Mohite, & R.H. Dauskardt, “Mechanical integrity of solution-processed perovskite solar cells”, Extreme Mechanics Letters, 2016, DOI: 10.1016/j.eml.2016.06.006

Contributing Author Publications

-

J.P. Chen, F. Hilt, N. Rolston, & R.H. Dauskardt, “Scalable open-air deposition of compact ETL TiOx on perovskite for fullerene-free solar cells”, in progress

-

J. Zhang, Y. Ding, G. Jiang, A. Flick, W.J. Scheideler, N. Rolston, & R.H. Dauskardt, “Low-temperature, open-air sprayed SnO2 nanocomposite for scalable perovskite solar cells”, in progress

-

O. Zhao, Y. Ding, Z. Pan, N. Rolston, J. Zhang, & R.H. Dauskardt, “Open-air plasma deposited multilayer thin-film moisture barriers”, ACS Applied Materials and Interfaces, 2020, DOI: 10.1021/acsami.0c01493

-

A.D. Printz, O. Zhao, S.S. Hamann, N. Rolston, O. Solgaard, & R.H. Dauskardt, “Self-aligned concentrating immersion-lens arrays for patterning and efficiency recovery in scaffold-reinforced perovskite solar cells”, Applied Materials Today, 2020, DOI: 10.1016/j.apmt.2020.100704

-

L. Bertoluzzi, C.C. Boyd, N. Rolston, J. Xu, B.C. O’Regan, & M.D. McGehee, “Mobile ion concentration measurement and open-access band diagram simulation platform for halide perovskite solar cells”, Joule, 2020, DOI: 10.1016/j.joule2019.10.003

-

M.Q. Hovish, N. Rolston, K. Bruening, F. Hilt, C. Tassone, & R.H. Dauskardt, “Crystallization kinetics of rapid spray plasma processed multiple cation perovskites in open air”, Journal of Materials Chemistry A, 2019, DOI: 10.1039/C9TA07980G

-

Y. Li*, W. Zhou*, Y. Li*, W. Huang, Z. Zhang, G. Chen, H. Wang, G.H. Wu, N. Rolston, R. Vila, W. Chiu, & Y. Cui, “Unravelling atomic structure and degradation mechanism of electron beam-sensitive hybrid organic-inorganic halide perovskite by cryogenic electron microscopy”, Joule, 2019, DOI: 10.1016/j.joule.2019.08.016

-

W.J. Scheideler, N. Rolston, O. Zhao, J. Zhang, & R.H. Dauskardt, “Rapid aqueous spray fabrication of robust NiO: A simple and scalable platform for efficient perovskite solar cells”, Advanced Energy Materials, 2019, DOI: 10.1002/aenm.201803600

-

M.Q. Hovish, N. Rolston, F. Hilt, Q. Xiao, & R.H. Dauskardt, “Open air plasma deposition of superhydrophilic titania coatings”, Advanced Functional Materials, 2019, DOI: 10.1002/adfm.201806421

-

S.I. Na, Y.H. Seo, Y.C. Nah, S.S. Kim, H. Heo, J.E. Kim, N. Rolston, R.H. Dauskardt, M. Gao, Y. Lee, & D. Vak, “High performance roll-to-roll produced fullerene-free organic photovoltaic devices via temperature-controlled slot die coating”, Advanced Functional Materials, 2019, DOI: 10.1002/adfm.201805825

-

D. Angmo, X. Peng, J. Cheng, M. Gao, N. Rolston, K. Sears, C. Zuo, J. Subbiah, S.S. Kim, H.C. Weerasinghe, R.H. Dauskardt, & D. Vak, “Beyond fullerenes: Indacenodithiophene-based organic charge transport layer towards upscaling of low-cost perovskite solar cells”, ACS Applied Materials & Interfaces, 2018, DOI: 10.1021/acsami.8b04861

-

L. Zhao, N. Rolston, K.M. Lee, X. Zhao, M.A. Reyes‐Martinez, N.L. Tran, Y.W. Yeh, N. Yao, G.D. Scholes, Y.L. Loo, A. Selloni, R.H. Dauskardt, & B.P. Rand, “Influence of bulky organo-ammonium halide additive choice on the flexibility and efficiency of perovskite light-emitting devices”, Advanced Functional Materials, 2018, DOI: 10.1002/adfm.201802060

-

S.G. Prolongo, A.D. Printz, N. Rolston, B.L. Watson, & R.H. Dauskardt, “Poly (triarylamine) composites with carbon nanomaterials for highly transparent and conductive coatings”, Thin Solid Films, 2018, DOI: 10.1016/j.tsf.2017.11.025

-

F. Hilt, M.Q. Hovish, N. Rolston, & R.H. Dauskardt, “Rapid route to efficient, scalable, and robust perovskite photovoltaics in air”, Energy and Environmental Science, 2018, DOI: 10.1039/C8EE01065J

-

R. Cheacharoen, N. Rolston, D. Harwood, K.A. Bush, R.H. Dauskardt, & M.D. McGehee, “Design and understanding of encapsulated perovskite solar cells to withstand thermal cycling”, Energy and Environmental Science, 2018 , DOI: 10.1039/C7EE02564E

-

K.A. Bush*, A.F. Palmstrom*, Z.J. Yu*, M. Boccard, R. Cheacharoean, J.P. Mailoa, D.P. McMeekin, R.L.Z. Hoye, C.D. Bailie, T. Leijtens, I.M. Peters, M.C. Minichetti, N. Rolston, R. Prasanna, S. Sofia, D. Harwood, W. Ma, F. Moghadam, H.J. Snaith, T. Buonassisi, Z.C. Holman, S.F. Bent, & M.D. McGehee, “23.6%-efficient monolithic perovskite/silicon tandem solar cells with improved stability”, Nature Energy, 2017, DOI: 10.1038/nenergy.2017.9

-

J.H. Kim, I. Lee, T.S. Kim, N. Rolston, B.L. Watson, & Reinhold H. Dauskardt, “Understanding mechanical behavior and reliability of organic electronic materials”, MRS Bulletin, 2017, DOI: 10.1557/mrs.2017.3

-

W. Greenbank, N. Rolston, E. Destouesse, G. Wantz, L. Hirsch, R.H. Dauskardt, & S. Chambon, “Improved mechanical adhesion and electronic stability of organic solar cells with thermal ageing: the role of diffusion at the hole extraction interface”, Journal of Materials Chemistry A, 2017, DOI: 10.1039/C6TA09665D

-

B.L. Watson, N. Rolston, K.A. Bush, T. Leijtens, M.D. McGehee, & R.H. Dauskardt, “Cross-linkable, solvent-resistant fullerene contacts for robust and efficient perovskite solar cells with increased JSC and VOC”, ACS Applied Materials & Interfaces, 2016, DOI: 10.1021/acsami.6b06164

-

M. Corazza, N. Rolston, R.H. Dauskardt, S.A. Gevorgyan, & F.C. Krebs, “Role of stress factors on the adhesion of interfaces in R2R fabricated organic photovoltaics”, Advanced Energy Materials, 2016, DOI: 10.1002/aenm.201501927

-

H.C. Weerasinghe, N. Rolston, D. Vak, A. Scully, & R.H. Dauskardt, “A stability study of printed organic photovoltaic modules containing a polymeric electron-selective layer”, Solar Energy Materials and Solar Cells, 2016, DOI: 10.1016/j.solmat.2016.03.034

-

V. Balcaen, N. Rolston, S.R. Dupont, E. Voroshazi, & R.H. Dauskardt, “Thermal cycling effect on mechanical integrity of inverted polymer solar cells”, Solar Energy Materials and Solar Cells, 2015, DOI: 10.1016/j.solmat.2015.07.019

Patents

-

US Patent 15943085 “Mechanical matrix for enhancing the thermomechanical and chemical reliability of optoelectronic device technologies” B.L. Watson, N. Rolston, A.D. Printz, & R.H. Dauskardt, October 4, 2018.

-

US Patent 15874527 “Method for forming perovskite layers using atmospheric pressure plasma” F. Hilt, M.Q. Hovish, N. Rolston, & R.H. Dauskardt, July, 19, 2018.

-

US Provisional Application 62/628624 “Lens array for the patterning of photoresist by maskless lithography” N. Rolston, A.D. Printz, S.S. Hamann, O. Solgaard, & R.H. Dauskardt, February 9, 2018.

-

US Provisional Application 62/479803 “Synthesis and use of azide-functionalized nodes for cross-linking materials containing organic components” B.L. Watson, N. Rolston, & R.H. Dauskardt, March 31, 2017.

Conference Proceedings and Presentations

-

N. Rolston & R.H. Dauskardt, “Rapid open-air fabrication of manufacturable perovskite solar modules”, Stanford University Materials Science and Engineering Colloquium, April 17, 2020. Oral Presentation

-

N. Rolston, W.J. Scheideler, A. Flick, J. Zhang, O. Zhao, J. Chen, & R.H. Dauskardt, “Rapid open-air fabrication of efficient and stable perovskite solar modules”, Materials Research Society Fall Meeting, Boston, MA, December 6, 2019. Oral Presentation

-

L. Bertoluzzi, N. Rolston, C.C. Boyd, J. Xu, R. Prasanna, B.C. O’Regan, & M.D. McGehee, “Simulating the band diagram of your own perovskite solar cell with an open-access online platform”, Materials Research Society Fall Meeting, Boston, MA, December 6, 2019. Oral Presentation

-

N. Rolston & R.H. Dauskardt “Design of stable and scalable perovskite solar cells with improved mechanical properties”, Materials Research Society Fall Meeting Graduate Student Award Symposium, Boston, MA, December 3, 2019. Oral Presentation

-

N. Rolston & R.H. Dauskardt “Design of scalable and stable perovskite solar cells”, Virginia Tech Future Faculty Development Program, Blacksburg, VA, November 12, 2019. Oral Presentation

-

N. Rolston, W.J. Scheideler, A. Flick, J. Chen, O. Zhao, J. Zhang, & R.H. Dauskardt, “Rapid open-air fabrication of scalable and stable perovskite solar modules”, Materials Science and Engineering Centennial Celebration, Stanford, CA, October 30, 2019. Poster Presentation

-

N. Rolston, K.A. Bush, A.D. Printz, M.Q. Hovish, F. Hilt, W.J. Scheideler, M.F. Toney, M.D. McGehee, & R.H. Dauskardt, “Engineering stress in perovskite solar cells to improve stability”, International Conference on Materials for Advanced Technologies, Marina Bay Sands, Singapore, June 26, 2019. Oral Presentation

-

N. Rolston, W.J. Scheideler, A. Flick, J. Zhang, O. Zhao, & R.H. Dauskardt, “Accelerated scaling to rapid open-air fabrication of durable perovskite solar modules”, IEEE Photovoltaic Specialists Conference Solar Energy and Technologies Office Session, Chicago, IL, June 19, 2019. Poster Presentation

-

N. Rolston, K.A. Bush, A.D. Printz, A. Gold-Parker, M.D. McGehee, M.F. Toney, & R.H. Dauskardt, “Engineering stress in perovskite solar cells to improve stability”, Materials Research Society Spring Meeting, Phoenix, AZ, April 23, 2019. Oral Presentation

-

I. Lee, N. Rolston, & R.H. Dauskardt, “Understanding molecular weight effect on low-temperature processed hole transport layer (PTAA) for robust wearable electronics” eWear Symposium, Stanford, CA, September 13, 2018.

-

O. Zhao, A.D. Printz, N. Rolston, S.S. Hamann, O. Solgaard, & R.H. Dauskardt, “Multifunctional lens arrays for patterning and photon management in compound perovskite solar cells” eWear Symposium, Stanford, CA, September 13, 2018.

-

N. Rolston, A.D. Printz, J.M. Tracy, R.H. Dauskardt, “Effect of composition and microstructure on the mechanical stability of perovskite solar cells” IEEE Photovoltaics Specialists Conference, Waikoloa, HI, June 14, 2018.

-

R. Cheacharoen, K.A. Bush, N. Rolston, D. Harwood, R.H. Dauskardt, & M.D. McGehee, “Damp heat, temperature cycling and UV stress testing of encapsulated perovskite photovoltaic cells”, IEEE World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, June 14, 2018. Conference Proceeding, DOI: 10.1109/PVSC.2018.8547430

-

N. Rolston, A.D. Printz, F. Hilt, M.Q. Hovish, K. Bruning, C.J. Tassone, & R.H. Dauskardt, “Spray plasma processing of barrier films deposited in air for improved stability of flexible electronic devices”, IEEE International Interconnect Technology Conference, Santa Clara, CA, June 4, 2018. DOI: 10.1109/IITC.2018.8430405

-

A. Printz, N. Rolston, S.S. Hamann, O. Zhao, O. Solgaard, & R.H. Dauskardt, “Scaffold-reinforced perovskite compound solar cells with integrated light management”, Materials Research Society Spring Meeting, Phoenix, AZ, April 6, 2018.

-

M.Q. Hovish, F. Hilt, N. Rolston, K. Bruening, & R.H. Dauskardt, “Scalable and rapid spray plasma processing of single and multiple cation perovskites”, Materials Research Society Spring Meeting, Phoenix, AZ, April 6, 2018.

-

N. Rolston, A.D. Printz, J.M. Tracy, R.H. Dauskardt, “Effect of composition and microstructure on the mechanical stability of perovskite solar cells”, Materials Research Society Spring Meeting, Phoenix, AZ, April 5, 2018.

-

N. Rolston, A.D. Printz, F. Hilt, M.Q. Hovish, K. Bruning, C.J. Tassone, & R.H. Dauskardt, “Spray plasma processing of barrier films deposited in air for improved stability of flexible electronic devices”, Materials Research Society Spring Meeting, Phoenix, AZ, April 4, 2018. Best poster award nominee

-

N. Rolston, A.D. Printz, J. Tracy, H.C. Weerasinghe, D. Vak, B.L. Watson, & R.H. Dauskardt, “Effect of composition and microstructure on stability of perovskite solar cells” Australian Center for Advanced Photovoltaics Conference, Melbourne, Australia, December 7, 2017.

-

N. Rolston, A.D. Printz, B.L. Watson, & R.H. Dauskardt, “Improved reliability of organic and perovskite solar cells” Australasian Community for Advanced Organic Semiconductors Symposium, Gold Coast, Australia, December 6, 2017.

-

N. Rolston, A.D. Printz, J. Tracy, & R.H. Dauskardt, “Effect of composition and microstructure on the mechanical stability of perovskite solar cells” Bay Area Photovoltaics Consortium Fall Meeting, Berkeley, CA,

-

N. Rolston, B.L. Watson, A.D. Printz, & R.H. Dauskardt, “Scaffold-reinforced perovskite compound solar cells for improved stability” Global Climate and Energy Project Student Lecture, Stanford, CA, July 24, 2017.

-

N. Rolston, A.D. Printz, F. Hilt, M.Q. Hovish, & R.H. Dauskardt, “Improved efficiency and stability of perovskite solar cells with submicron barrier films deposited in air” Bay Area Photovoltaics Consortium Spring Meeting, Stanford, CA, May 22, 2017.

-

F. Hilt, M.Q. Hovish, N. Rolston, & R.H. Dauskardt, “Ultrafast one-step deposition of perovskite thin films by atmospheric plasma curing” Materials Research Society Spring Meeting, Phoenix, AZ, April 20, 2017.

-

A.D. Printz, N. Rolston, B.L. Watson, & R.H. Dauskardt, “New concepts in reinforced, segmented perovskite solar cell design with polymer scaffolding” Materials Research Society Spring Meeting, Phoenix, AZ, April 18, 2017. Best poster award nominee

-

N. Rolston, A.D. Printz, F. Hilt, M.Q. Hovish, B.L. Watson, & R.H. Dauskardt, “Processes for robust, scalable, and stable perovskite solar cells” Materials Research Society Spring Meeting, Phoenix, AZ, April 17, 2017.

-

N. Rolston, F. Hilt, M.Q. Hovish, A.D. Printz, & R.H. Dauskardt, “Atmospheric plasma deposition for stable, scalable, and robust perovskite solar cells” American Chemical Society Spring Meeting, San Francisco, CA, April 4, 2017.

-

N. Rolston, A.D. Printz, B.L. Watson, & R.H. Dauskardt, “Reinforced perovskite solar cells designed with integrated polymer scaffolding for robust, efficient photovoltaics” American Chemical Society Spring Meeting, San Francisco, CA, April 2, 2017.

-

B.L. Watson, N. Rolston, K.A. Bush, A.D. Printz, & R.H. Dauskardt, “Overcoming the mechanical fragility of perovskite solar cells using novel cross-linking chemical additives and scaffolds” American Chemical Society Spring Meeting, San Francisco, CA, April 2, 2017.

-

N. Rolston, B.L. Watson, A.D. Printz, & R.H. Dauskardt, “Next-generation robust perovskite solar cells for improved stability” International Conference on Perovskite Solar Cells and Optoelectronics, Genoa, Italy, September 28, 2016.

-

N. Rolston, B.L. Watson, & R.H. Dauskardt, “Reinforcing perovskites for improved mechanical stability of solar cells” Materials Research Society Spring Meeting, Phoenix, AZ, March 31, 2016.

-

N. Rolston, B.L. Watson, & R.H. Dauskardt, “Thermomechanical properties of perovskite solar cells” Materials Research Society Spring Meeting, Phoenix, AZ, March 28, 2016.

-

N. Rolston, B.L. Watson, & R.H. Dauskardt, “Crosslinkable Materials for Increased Thermomechanical Reliability of Perovskite Solar Cells” KAUST Solar Future Conference, Thuwal, Saudi Arabia, November 8, 2015.

-

N. Rolston, B.L. Watson, & R.H. Dauskardt, “Improved Mechanical Stability of Perovskite Solar Cells”, Bay Area Photovoltaics Consortium Fall Meeting, Berkeley, CA, October 20, 2015.

-

N. Rolston, V. Balcaen, S.R. Dupont, E. Voroshazi, & R.H. Dauskardt, “Thermal Cycling of Polymer Solar Cells”, Materials Research Society Spring Meeting, San Francisco, CA, April 8, 2015.

Awards

-

Materials Research Society Graduate Student Award, Gold (2020)

-

Future Faculty Development Program Award at Virginia Tech (2019)

-

Materials Research Society Graduate Student Award, Silver (2019)

-

Gerald J. Lieberman Fellowship (2019-2020)

-

National Science Foundation Graduate Research Fellowship (2015-2018)

-

Ford Foundation Graduate Research Fellowship (2015-2019)

-

National Defense Science and Engineering Graduate Fellowship

-

Stanford EDGE-STEM Fellowship (2015-2017)